Respirator Filters Exchange Safety Program

Table of Contents

Toggle

Having a Respirator Filters Safety Program logging the exchange of old for new HEPA Filters is an act of Due Diligence. Depending on the Hazards within your scope of work, filters might need to be swapped out daily, weekly, or they might even last months. But just changing them out and disposing of the old ones is only half the task with in the Respirator Filters Safety Program. A detailed log is vital, just in case you're ever asked for proof of when new filers were issued.

Types of Filers

What are the main types of filters used in construction and industry as a whole.

There are 3 main types of filers used. Particulate filters, Filter for Gas, Fumes, and Vapors, and then there's Combination Filters. Within those 3 groups are various types that perform at different filtration levels. Identifying these filters is a uniform system of grading and usage type. In addition, a color is used to identify the differences in particulate filtration and for gas fume vapor filers colored strips are used for type identification as well.

Particulate Filters (HEPA)

If you did a internet search for the definition of the acronym “HEPA” 3 different answers will come up. These 3 are as follows:

-

- High Efficiency Particulate Air

- High Efficiency Particulate Arresting

- High-Efficiency Particulate Absorbing

However, it’s the 1st one we use in Construction and Industry. Yet amongst all these filters there is one constant. They are all designed to filter out particulates in size at .3 microns or bigger. If the filtration was designed to filter out smaller particulates, it could cause breathing problems for a large number of the workforce.

Rating and Filtration

High Efficiency Particulate Air filter or HEPA are rated by a letter first, then a number. Either P, R, or N will be followed by a number, usually 95, 99, 100. The letter rating is in reference to if there is oil in the air environment your working in. The numbers are reference to the percentage of particulate filtration at .3 microns and bigger

|

P |

Oil Proof (to a point) |

95 |

Filter efficiency is 95% at .3µm+ |

|

R |

Oil Resistance (day use only) |

99 |

Filter efficiency is 99% at .3µm + |

|

N |

None Oil Proof (disposable) |

100 |

Filter efficiency is 99.97% at .3µm + |

Why is 100 not 100%

Why is 100 not filtering out 100% of the particulates. After all, 99 and 95 are true to the percentage. The answer is, Liability. If manufactures said the filtration is 100% efficient, that claim is then stating a certainty, or a guarantee. In turn that would open the flood gates to lawsuits for anybody who remotely sustained a respiratory injury will working in an environment where a respirator & filters are required. The results would be chaos in the PPE and safety communities. Even HEPA filters on tools designed to capture expelled dusts and particulates DO NOT Guarantee 100% capture. That’s why we still use Respirators even if tools have attached filters.

Gas, Fumes, and Vapors

These by-products can be smaller than .3 microns. Therefore, a different type of filtration must be used. Different products are used for these filters, yet most common are charcoal based. These filters perform like their magnetically charged and draw in the contaminants, creating a reaction that sticks or holds the gas to the filter. After usage, its always a good idea to remove your filters and seal them in a zip lock freezer. This prevents saturation during non usage times. Each filter will list what its intended usage is for. As well some even have an imbedded slider that indicated when maximum saturation is completed.

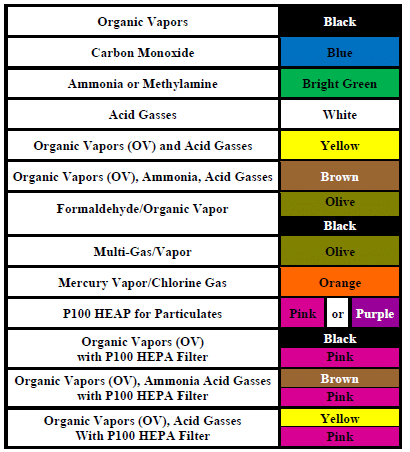

Respirator Filter Color Codes

Honeywell North and 3M Respirator Filters

Honeywell North and 3M - Filters and Cartridges

You can also find more information on the following links:

Supply

Vital in a Respirator Filters Safety Program is Supply. Always having new filters for workers access is essential. At no time should supplies ever run out forcing workers to continue using dirty and saturated filters. In fact, each worker should sign out an extra set and secure them in their respirator cleaning kit.

Storage

Not only workers need to be concerned in the method of HEPA Filter Storage, managers and or supervisors who administer the program need to be as well. Your office area safety supply storage or supply locker should never be in any place where damage could occur to or products could go missing. Keep away for excessive heat, moisture, cold, or high traffic areas.

Extra Protection when Stored

As previously noted for gas filers, it's also a good idea to store all filters in a secondary freezer bag in pairs. Original packaging is a light weight plastic that tears very easily. Freezer bags are extra added protection that can then be given to the workers so the filters are not just hung on a wall with the respirator. As well issuing large freezer bags to fit their whole respirator in helps keep them clean during non usage times.

Respirator Filters Exchange Safety Program

Filter Expiry Dates

Shelf life of unopened sealed Respirator Filters can range from 5 to 10 years maximum. However, open packaging and not used filers are good for 6 months. You can stretch that 6 months if you reseal your filters after every usage, depending on the filtered contaminants. Depending on the scope of work with in your trader group, intervals will differ on when its time to exchange your filters for new ones.

Examples

I’ve seen Asbestos removal company workers issued new filers daily. For masonry and concrete cutting etc. where do to the situation silica dust isn’t engineered out, a maximum usage time would be 40 hours or a standard work week. The best rule of thumb would be, if it’s becoming increasingly labour intensive to breath, or you can smell and or taste what should be filtered out, GET NEW FILTERS. It’s always better practice to issue your workers new filers before full saturation is achieved.

Respirator Filters Safety Program Records and Logs

Having a detailed record sheet or logbook for your Respirator Filters Exchange Safety Program can be formatted by illustrating the time/dates of when a workers receives new filters is always good due diligence. Build a table using Excel or any table/ grid program. Start with the workers name, followed by their respirator (make and model), next add the filter issued, the date it was issued, and finally the workers initials. You can even have a block describing the contaminants the filters are used for, and the workers Respirator Fit Test Date. Add any other relevant information you feel is necessary.

HEPA Filter Exchange LogRespirator Filters Safety Program Excel Spreadsheet

Or if you wish please feel free you use this Respirator Filters Safety Program Excel Program