Hard Hats and the New WorkSafe BC Regulations

Table of Contents

Toggle

Hard Hats and the New WorkSafe BC Regulations

Hard Hats and the New WorkSafe BC Regulations came into effect on September 1st 2021 and has created a lot of talk and chatter in the construction world and safety community as a whole. Looking into the amendment within Part 8 and the PPE Regulations, hopefully some clarity can be the result. With that being said, I do not intend to purposefully cause insult or offence to anybody. Yet keep in mind that no part of this article will be sugar coated in the least. To do so, can cause the message and information of real safety to be lost in translation.

Hard Hats

Before we get into the new regulation, one question I've been asked is, where did hard hats come from. The universal answer come right from Wikipedia.

Hard Hat History

In the early years of the shipbuilding industry, workers covered their hats with pitch (tar), and set them in the sun to cure, a common practice for dock workers in constant danger of being hit on the head by objects dropped from ship decks.

Unsupported Claim

Management professor Peter Drucker credited writer Franz Kafka with developing the first civilian hard hat while employed at the Worker's Accident Insurance Institute for the Kingdom of Bohemia (1912), but this information is not supported by any document from his employer.[1]

True Inventor of the Hard Hat

In the United States, the E.D. Bullard Company was a mining equipment firm in California created by Edward Dickinson Bullard in 1898, a veteran of the industrial safety business for 20 years. The company sold protective hats made of leather. His son, E. W. Bullard, returned home from World War I with a steel helmet that provided him with ideas to improve industrial safety.

Bullard Patent

In 1919 Bullard patented a "hard-boiled hat" made of steamed canvas, glue and black paint. That same year, the U.S. Navy commissioned Bullard to create a shipyard protective cap that began the widespread use of hard hats. Not long after, Bullard developed an internal suspension to provide a more effective hat. These early designs bore a resemblance to the steel M1917 "Brodie" military helmet that served as their inspiration.

Turbans

According to WikiHow who acquired their information from religious sources, the traditional turban consists of a two-part system of cloth. These lengths of cloth are tied up and around their heads containing the person hair. In addition, a Guardian article states the cloth can be 40 meters in length.

History of the Turban

"Kes" or sometimes known as "Kesh" is the religious term used by Sikhs where as they must leave their hair in an unaltered state. This was what Guru Gobind Singh, the 10th and last human guru of the Sikh, formed in 1699 as part of the the Khalsa. As part of the 5Ks of the faith for baptized Sikhs, he wanted to create a unique separate identity. One main purpose was for a way of distinguishing them from Hindus or Muslims.

Different Styles

- Domalla: A double-length turban of 9 or more meters of cloth

- Pagriv: A double width turban 4.5 to 5.5 meters of cloth

- Dastar: A single turban of 3 1/2 to 5 1/2 meters of cloth

- Keski: A short turban of just under 2 meters to almost 3 of cloth

- Patka: A square of half to 1 meter of cloth, tied over the joora (top knot of the main hair covering) and head

- Fifty: A half meter worn beneath a turban, usually in contrasting or decorative colors

New WorkSafe BC Regulations

Moving forward, what did the old regulations say and what's the new written regulation going to look like? Well, you can see both right here. .

Part 8.11 (1) Repealed

"Safety headgear must be worn by a worker in any work area where there is a danger of head injury from falling, flying or thrown objects, or other harmful contacts."

Part 8.11 (1) Revised

Before a worker starts a work assignment in a work area where there is a risk of head injury to the worker from falling, flying or thrown objects, or other harmful contacts, the employer must take measures to

(a) eliminate the risk, or

(b) if it is not practicable to eliminate the risk, minimize the risk to the lowest level practicable by applying the following control measures in order of priority:

(i) engineering controls;

(ii) administrative controls

(iii) requiring the worker to wear safety headgear.

The Meaning Behind the Words

Let’s look at the new regulation line by line and decipher the meaning behind the words. First off, at the very beginning what’s said in Part 8.11 (1) is “Before a worker starts a work assignment in a work area where there is a risk of head injury to the worker from falling, flying or thrown objects, or other harmful contacts, the employer must take measures to”. After which sub parts are listed. First let’s examine what was just said.

Falling Objects

For the term “Falling Objects” there is a phase coined by Theodore Sedgwick and used in his book, “Hints to my Countrymen,” published in 1826. “What Goes Up, Must Come Down”. This means if an object is not fastened down and secured, a hazard does exist resulting in the risk of a falling object.

Flying Object

This can also cause the action of a “Flying Object”, On a Hi-Rise project, the higher you build the windier it gets. Without the building envelope installed, wind can pick up a small piece of overlooked debris and fly it across a site, potentially hitting a worker.

Thrown Objects

As far as the term “Thrown Objects” let me make one thing perfectly clear right now. At NO time should anything be thrown on a jobsite. Tools if needed should be passed hand to hand from worker to worker, never tossed or thrown. This goes the same for Materials, Fasteners, whatever the object is. Purposely throwing an object of any kind results in nobody having any control over the intended destination it was meant to arrive at. A hazard has just been created where it never should have existed in the first place, thereby potentially putting somebody at risk.

Sub part (a) “eliminate the risk”

This is an aspect of safety conducted to the best of every person on a job sites abilities, all day every day. It’s the first step before any trade’s person starts their job-related task. As an example, a carpenter needs to cut lumber to a specific size. He needs to set up a table and a portable Ratio Arm Saw in an area close to where the installation will take place. Yet there’s some wood debris all over the floor. To eliminate the risk of injury from the hazard “Trips and Falls”, the debris is cleaned up and remove.

Sub Part (b) If it is Not Practicable to Eliminate the Risk

“if it is not practicable to eliminate the risk, minimize the risk to the lowest level practicable by applying the following control measures in order of priority”:

This is always conducted and is one of the main duties of all on-site safety personal in construction and industry. If we can’t eliminate a risk from a potential hazard, we look at the other aspects of controls to increase safety.

Subsection (i) “engineering controls”

This is short is something built or installed to increase the safety for workers. A good example is what you’ll see on every construction jobsite. Guardrails with Toeboards. An engineering control designed and installed to eliminate the potential fall of workers, whereas the toeboards are in place to eliminate objects from falling onto others below. On a Hi-Rise building, orange colored Safety Fencing is also installed to prevent the later.

Subsection (ii) “administrative controls”

This is conducted at the very beginning of any new project, before workers or subtrade's begin their contracts and throughout the project’s timeframe. So, what’s an administrative control? It starts with the per-planning of a project, the safety program in place, employee training, site safety rules, pre job worker orientations, posted signage, and so much more. All designed to convey information and /or instructions from one source to another on ways and means of how to be safe at work.

Subsection (iii) “requiring the worker to wear safety headgear”

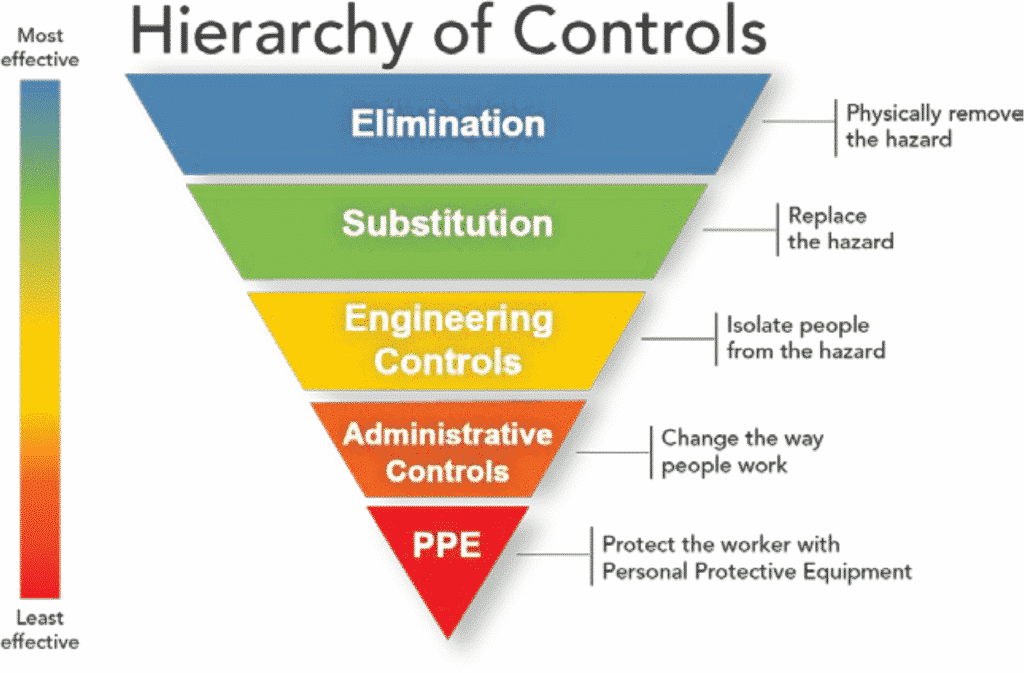

In the Hierarchy of Controls, this is the last line of defence from a worker I injury from something falling and hitting their head. There is another reason why we wear Hard Hats. Side impacted injuries as well. Yet there is a very good reason why it’s at the bottom of the HOC Triangle. It is the last line of defence and if only used as a single control, the risk of worker injury increases dramatically.

Safety vs. Religion or Culture

A lot of talk has suggested that religious concerns are now trumping safety. That it’s a Safety vs. Religion or Culture scenario. That may be true in some respect. However, the new regulation is NOT new at all. It’s always been there and written throughout the entire regulations across the board. The only thing is, that in Part 8 of the WorkSafe BC Regulations, it’s been written down and outlined point by point.

Hierarchy of Controls

Hierarchy of Controls

It’s what safety professionals use and do with in the course of our duties. That is, using the Hierarchy of Controls as the way we deal with Risks and Hazards in all working environments. It’s the bases of safety in general. With that being said, let me also make one further statement that I hope will clearly make those who don’t understand the full scope of construction or industry, comprehend the reality.

Construction is Inherently Dangerous

Construction is inherently dangerous as are a lot of other working environments. If the working world was perfect coupled with all Risks and Hazards eliminated, there wouldn’t be any requirement for Site Safety Professionals and Occupational First Aid Attendants on any construction site. The need for a legislative governing authority like WorkSafe BC wouldn’t exist. But in reality, it’s just not that way at all. Nor will it ever be. At least not in the near future.

Snowballing Effect

One possible result of the new formatted regulation is potently opening the door for abuse and a snowballing effect of other forms of PPE not being utilized on a construction jobsite. It also creates a shift of onus for personal safety away from the worker, and could place blame for every potential negative situation that results in a head injury on anybody else but said worker. Frankly, that moves even further away from people using their own common sense prior to approaching a hazardous situation.

Prime Contractors Rules

One concern about this whole aspect of a re-written regulation change is a Prime Contractors internal site safety rules, policies and regulations. Very common in construction are sites completely fenced off with gated entrances and signage stated PPE must be worn past this point. In most if not all sites, that list of PPE consists of

- CSA approved work boots

- Hi-Vis Vests or other

- Eye Protection

- Hearing Protection

- Hard Hat Head Protection

Safety Policy

It’s always been policy that if a safety rule on a construction site is more stringent and creates a less of a chance for personal injury of a worker then a WorkSafe BC Regulation, then that’s the rule that must be adhered to and the one WorkSafe BC OSOs will enforce. Now the question needs to be asked, how does that play out.

Abuse of the New Written Regulation

As already mentioned, abuse of the new written regulation is already apparent. Workers not wearing hard hats are walking in areas and under other workers at heights conducting tasks where an object can fall. They’re not looking up before entering an area, and the attention span for personal safety on site is diminishing rapidly. For those not wearing hard hats in construction, your personal awareness of everything around you has increased exponentially. Complacency and / or lack of full attention will result in injury more than other workers.

Injury Claims

If any person for religious reasons decides to exercise their rights and be exempt from wearing a protective hard hat, in time I think stats will show head injury claims rising. With that being said, if that same worker invokes religious exemption, then they should be 100% responsible for any legitimate accident resulting in a head injury. Meaning unless fault can be laid on another workers mishap. For example, dropping a hammer when it should have been lanyard off. Then by default they should also be exempt from filing any and all head injury claims with Worksafe BC. You can't have your cake and eat it too.

Safety Control Zone

We're all aware that any area below a worker doing a task at heights should have a safety control zone erected. Doing that prior to stating the task is conscientious. Its purpose being the prevention of others from blindly walking under the tasked area. However, on large projects that are on a small land footprint, excessive ground level control zones can clog a site and diminish access and egress to a point seriously impacting production as a whole.

Compromise

If accommodating for religious concerns was the intention of this new written regulation, then why shouldn’t compromise be part of both sides of the equation. As previously mentioned at the beginning, several different styles of Turbans can be worn. Some of which use considerably less cloth than others, thereby decreasing the overall girth of a turban. Nothing in Sikhism says this can't be done on a construction site or any work environment. The only reason to refuse to use less cloth is the belief that more cloth means better protraction. That’s reasoning would come from a lack of knowledge, training and experience.

A Safer Result

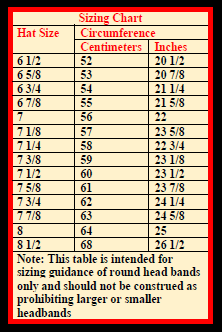

Removing a Turban so a Hard Hat can be warn is not what is being asked. Not using so much cloth material is. Still being able to contain their hair would be a much safer result. Thereby a larger hard hat can be used, and a chin strap can be attached helping to keep the hard hat fastened to the worker, Safety and Religion are satisfied as this video will demonstrate .

Why Even Sikhs Need to Wear Hard Hats

There’s a reason why they call it a “Brain Bucket”. It protects your brain as this short demonstration shows. No cloth turban is going to protect a worker from a falling object like a wrench or a framing hammer. A 32 oz framing hammer falling from the 3rd floor can hit a worker below in 2.5 seconds and be traveling upwards of 90 km/h. Cloth will not protected. Death can be a real certainty.

Religion, Culture, and Politics

With this written change in regulation, what now has been brought into the realm of safety is, Religion, Culture, Politics, and Court Cases. None of which should ever influence the ultimate goal of any safety program. The complete Health and Safety of all worker in a dangerous occupation has to be equal. The other 4 mentioned realms could create a divide amongst workers. It could cause racial tensions in some workplaces.

“Two is One, and One is None”

There is a concept term I use in my duties as a safety professional in regards to the Hierarchy of Controls. “Two is One, and One is None”. What this means is, if we just rely on one single part of the HOC and a failure of that single part occurs, then there is NO backup preventing a worker injury. It’s that simple. Utilizing as many if not ALL aspects of the HOC is a “Best Practice” for safety as a whole. PPE most definitely included.

Tied Hands

Not only does this new written regulation in some ways tie our hands from using all aspects of a safety program, it raises the question of lawsuits. What if I make a decision when it comes a safety related situation that not all of the upper actions of a HOC can be satisfied. Knowing a Hard Hat is still an option to increase safety, I decide it must be used. Yet the worker is wearing a turban and refuses for religious and cultural reason. I stand by my decision there by not allowing this worker to do whatever it is they needed to do. Have I just opened the door for a third-party legal matter?

Appearance of Negative Actions

There are a lot of avenues a person can take if they feel they have been wronged and wish to challenge a decision in this regard. Certainly, WorkSafe BC is one, another is The BC Human Rights Tribunal, and of course they can also hire a lawyer and file a lawsuit using the court system. Any of which that are used, once a formal application is filed claiming in what they perceive as a human rights violation, it become public. Even if as a safety person making a safety call I was protected from any such legal action, just the appearance of negative actions being filed against a safety professional can and most likely would be attached to them forever.

Catch 22

With computers and the internet, open sources of information and research, that stigma will follow a career forever. One can clearly see in a worse case scenario even if your innocent, it can be a career destroyer. How many are willing to put their career profession on the line in the course of doing what’s right as their profession ethically dictates. It’s not just a catch 22. It’s carrying a unsheathed double edged sword while being tripped by a catch 22 and becoming wedged between a rock and a hard place.