Hard Hat Directly Attached LED Tape Lights

Table of Contents

ToggleAre They Allowed?

Notwithstanding, the question “Hard Hat Directly Attached LED Tape Lights, Are They Allowed?” has come to light. Research into hard hat regulations and from the language used, I would say “YES”. In the first place, in ALL Occupational Health and Safety, first and foremost is the worker's safety. Moreover, workers must conduct their work activities in the safest way possible. Anything short of that is unacceptable. With this intention, directly attached LED tape lights to hard hats can and do exceed the basic safety requirements.

When it comes to the safety of all workers in British Columbia Canada, the Province of BC has laid out the rules in the Workers Compensation Act. That act has been formatted into the WorkSafe BC Occupational Health and Safety Regulation that governs the activities of workers. In addition to those regulations, 2 more bodies, as well as the manufacture, have regulations.

In concert with the manufacturer’s recommendations, the main legislative governing bodies are as follows.

- WorkSafe BC Regulations and their associated Guidelines, Safety Headgear 8.11, Guidelines Part 8 Safety Headgear, Part 18: Traffic Control, Part 18 OHS Guidelines

- CSA Standard, CAN/CSA-Z94.1-92

- Traffic Management Manual for Work on Roadways, 2015 Office Edition

and the manufacture used for the SEEME-NOW Hard Hat

For the most part, the rules and regulations illustrated below are primarily alluding to the use of hard hats by Flaggers or Traffic Control Persons.

Regulations, Rules and Explanations

To start with, in order to comply with the aforementioned regulations, we will start by examining the related regulations. To start with, let us go to the related section in the CSA Standards.

CSA Standard

5.7.2 Additions of Decals, Laminates, Stickers, or Tape to Headgear

Any decals or laminates applied to the protective headgear shall be compatible with the surface material and known not to affect adversely the characteristics of the materials used in the protective headgear. Non-metallic stickers or reflective tape placed at least 13 mm (1/2 inch) above the edge of the brim will not affect the dielectric characteristics of headwear. The application of decals, laminates, stickers, or tape shall not compromise the ability of the user to inspect the headwear shell for damage.

LED tape lights are attached with 3M double stick tape. In addition, hot glue is also used for the attachment of cords and clips. Neither in anyways is toxic to the hard hat material. As well, are no more invasive than the reflective strips or stickers seen on hard hats. The Specification Sheet has a full list of materials related to this.

WorkSafe BC Regulations and their associated Guidelines

Following is the prime regulation for hard hats in the work environment. As you'll see, they basically defer to the CSA Standard.

8.11 General requirement

(1) Safety headgear must be worn by a worker in any work area where there is a danger of head injury from falling, flying or thrown objects, or other harmful contacts.

(2) Safety headgear must meet the requirements of one of the following standards

(a) CSA Standard CAN/CSA-Z94.1-05 or CAN/CSA-Z94.1-15, Industrial protective headwear – Performance, selection, care, and use;

(b) ANSI Standard ANSI/ISEA Z89.1-2009 or ANSI/ISEA Z89.1-2014, American National Standard for Industrial Head Protection.

(3) If a worker may be exposed to an electrical hazard the safety headgear must have an appropriate non-conductive rating.

(4) Chin straps or other effective means of retention must be used on safety headgear when workers are climbing or working from a height exceeding 3 m (10 ft), or are exposed to high winds or other conditions that may cause loss of the headgear.

(5) Repealed. [B.C. Reg. 381/2004, effective January 1, 2005.]

(6) Damaged headgear or headgear with missing, mismatched, or modified components must be removed from service.

The concern for some is the word "Modified" in (6). The consensus of the meaning of this word would refer to hard fastened devices that require or use nuts & bolts or screws to secure a device. Included with these examples would be drilling holes in the side of a hard hat for mounting. Devices such as cameras, or other light sources that are mounted with the aforementioned fasteners are strictly prohibited. LED tape lights are stuck on like stickers and reflective tape. They do not apply in the meaning of modifying. Another key point would be if the suspension harness had aftermarket straps stitched in or foam added for cushioning. That would be the definition of "Modify"

Following is the prime regulation for hard hats in the work environment. As you’ll see, they basically defer to the CSA Standard.

18.9 Operations during daytime

Each traffic control person must be provided with, and must use, all of the following:

(d) safety headgear of a high visibility colour with a strip of retroreflective tape across the top from front to back and on the sides;

G18.9 Safety headgear for traffic control persons

Background

Section 18.9 was added to the Regulation in 2007. The requirement to provide and use a high visibility colour for safety headgear for traffic control persons under Part 18 allows for a choice of a high visibility colour. Acceptable colours for safety headgear under Part 18 are provided in this guideline.

Description

The CSA Standard Z96-02, High-Visibility Safety Apparel, and WCB Standard: PPE 2 High Visibility Garment - Personal Protective Equipment Standard 2, provide acceptable high visibility colours for safety garments as fluorescent yellow-green, fluorescent orange-red and fluorescent red. These colours are acceptable for safety headgear provided to, and used by, traffic control persons under Part 18 of the Regulation. High visibility colours of equivalent luminance quality, as well as the orange colour specified in the Traffic Control Manual for Work on Roadways issued by the Ministry of Transportation, are also acceptable colours for traffic control persons' safety headgear.

The retroreflective tape strip on the safety headgear is to meet the specifications for VE Trim as set out in WCB Standard: PPE 2 High Visibility Garment - Personal Protective Equipment Standard 2.

To emphasize, the regulations already allow for reflective tape. Additional LED lighting just above the brim is not much of a stretch. Furthermore, all the reflective PPE worn by traffic control people doesn't reflect until a light source is directed at it. A constant source of LED light that remains with them at night could be and should be utilized.

G18.9(a) - Illuminated Traffic Control Paddles

Issued February 27, 2012

Regulatory excerpt

Section 18.9 of the OHS Regulation ("Regulation") states, in part:

Each traffic control person must be provided with, and must use, all of the following:

(a) a traffic control paddle meeting the requirements for a C-27H Traffic Control Paddle as specified in the Traffic Control Manual and, if necessary to control fatigue, a non-conductive support staff for the paddle;

Purpose of guideline

The purpose of this guideline is to clarify the acceptability of using illuminated traffic control paddles (TCPs) in traffic control operations.

Illuminated traffic control paddles

Recent developments in technology have allowed for the placement of lights (typically LEDs) along the outside edge of TCPs, providing illumination to the sign in an effort to increase the visibility of the sign, and consequently of the traffic control person and other workers.

One such design provides a ring of eight red LEDs around the perimeter of the red "Stop" side of the sign, and a similar configuration on the yellow "Slow" side of the sign. While LED lighting is not considered in the Traffic Control Manual (as defined in section 18.3 of the Regulation), such a configuration is referenced as acceptable in the U.S. Manual on Uniform Traffic Control Devices (MUTCD). LEDs arranged on a sign in this fashion can be an enhancement to visibility and safety.

They may be used if all other requirements specified in the Traffic Control Manual are met and followed; providing that the visibility and effectiveness of the TCP are in no way reduced or compromised.

Given that G18.9(a) is for the "acceptability of using illuminated traffic control paddles" with LED light, the next evolution would be on PPE. In fact, some safety stores in The States have high vis vests and gloves equipped with LED lights for flaggers and nighttime workers.

18.10 Operations during nighttime or poor visibility

(1) During the hours of darkness, or in other conditions of poor visibility, each traffic control person must be provided with and must use, in addition to the equipment required by section 18.9, a flashlight fitted with a red signalling wand.

Traffic Management Manual for Work on Roadways

5.4.1 TCP Apparel and Equipment

Personal protective clothing and equipment for TCPs shall comply with Parts 8 and 18 of WorkSafeBC’s Occupational Health and Safety Regulations and other standards as identified below.

1. Basic Requirements * Safety Headgear:

TCP hard hats shall comply with one of these standards:

- CSA Standard CAN/CSA-Z94.1-92, Industrial Protective Headwear

- ANSI Standard Z89.1-1986, American National Standard for Personnel Protection, Protective Headwear for Industrial Workers Requirements

- Japanese Industrial Standard JIS T8131-1990, Industrial Safety Helmets for Class AB or ABE Headgear

Hard hats shall be of a high-visibility colour with a band of retroreflective tape across the top from front to back and on the sides.

- WorkSafeBC permits fluorescent yellow-green, fluorescent orange-red, and fluorescent red colours.

- The hard hat shall have retroreflective material across the top from front to back and on the sides to make it clearly visible to drivers approaching from any angle.

4. Night Lighting

TCP stations shall be illuminated at night. If street lighting is available, TCPs should stand below the light to maximize front-of-body illumination. If temporary overhead lighting is being used, it shall not subject approaching drivers to excessive glare.

Manufacture of Hard Hat: PYRAMEX

Do not use paint, chemicals or solvents as they could reduce the impact and electrical properties.

Important to realize, like all PPE equipment, this manufacture states to never use paint, chemicals or solvents. To clarify, these products will deplete the hard hat structural properties of the material used in production. To emphasize, a phone call was placed to this manufacture where the question was asked if double stick tape or hot glue would affect the hard hats strength. The answer I received was "Not at All". Certainly, if the tape or glue affected the hard hat, stickers and reflective tape would also be disallowed.

* Proposed Amendments to soon to be added to Part 18 of the WorkSafe BC OHS Regulations

In a recent document posted on the WorkSafe BC website, some new amendments are being implemented by the end of this year 2019.

18.8 (d) makes the traffic control person stand out against the background or appear as conspicuous as possible to approaching traffic

Operations during daytime

18.9 (d) safety headgear of a high visibility colour marked with a strip of retroreflective tape across the top from front to back and a strip of retroreflective tape on each side, and

(e) other-equipment required by the risk assessment

Operations during darkness or poor visibility

18.10

(4) During the hours of darkness, or in other conditions of poor visibility, a location from which a traffic control person directs traffic must be illuminated by

(a) overhead street lighting, or

(b) if overhead street lighting is not available, temporary lighting that does not subject approaching road users to excessive glare.

Response to the New Proposed Amendments

- In part 18.8 (d) it says "makes the traffic control person stand out against the background". What better way to stand out against the background by applying lights to your PPE. Especially on a dark stormy day or at night. Fluorescent reflective striping is only functional once a light source is shined upon it.

- In 18.9 (e) a new regulation that falls within another section 18.3.1 (1) a risk assessment has to be performed prior to work activities. Within that assessment, a qualified person with the correct knowledge and experience can determine hard Had lighting is a required safety device for the risks at hand. These risks would be absent lighting sources, a dark environment, a high traffic area, additional visibility needed etc.

- 18.10 (4) (b) if no overhead light is available, the SEEME-NOW hard hat safety lights are classified as temporary lighting. Furthermore, the SEEME -NOW system in no way creates a glare creating a hazard to oncoming drivers. However, if you are now noticing the glare in the picture below, that is caused by the lenses, lack of filters, my inexperience in photography and using an android S8 phone camera. In reality with the naked eye or through a window absolutely no glare exists and I will be willing at any time I'm free to demonstrate this in real-time. Just call and then come on by.

Conclusion

In conclusion, the question “Hard Hat Directly Attached LED Tape Lights, Are They Allowed” is a YES in my opinion.

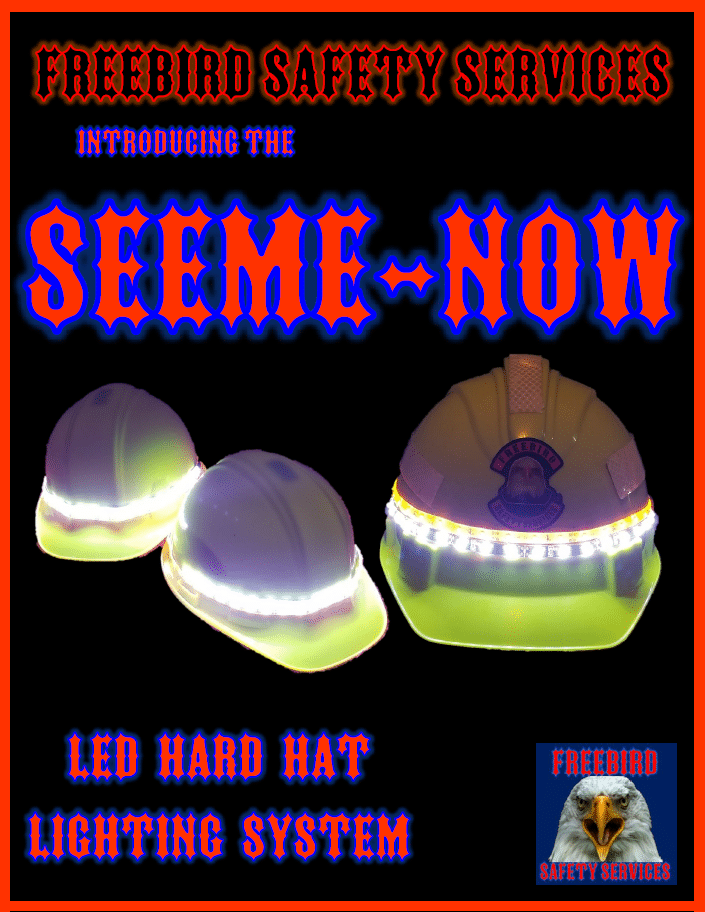

Figure 2.

All things considered, there is NO clear or decisive rule, regulation or suggestion to not allow such a device on a hard hat. After all, the factor of improved safety for those who use LED lights on a hard hat is clear. To put it another way, a worker is seen before lights reflect off the high vis PPE from a vehicle. In fact, the high vis properties are already being reflected from the LED lights. Despite the glare and poor quality of the camera, the picture in Figure. 2 shows how much a high visual lime green jacket is illuminated.

Picture Outline

To demonstrate, this is a mockup, outfitted with the exact same Class 3 reflective stripping as a TCP. To begin with, this picture was taken in a completely blacked out storage room. Absolutely no other light source was used except that of the SEEME-NOW LED Hard Hat Lighting System. Finally, taken from approx. 20 feet away you can clearly see the high vis jacket and the "Stop" side of the regulation C-027 Paddle that flaggers use. Hard Hat Directly Attached LED Tape Lights are the future.

Classes and Types of hard hats are:

Type 1 – protection from impact and penetration at the crown (top) and

Type 2 – protection from impact, penetration at the crown (top) and laterally (sides and back)

Each type is also available in the following classes:

E Class (20 000 V electrical rating) – non-conducting material (electrical trades)

G Class (2200 V electrical rating) – non-conducting material (general trades)

C Class C (no electrical rating)

The hard hat pressingly being used for the SEEME-NOW hard hat safety lights is the PYRAMEX HP14131 SL Series. As stated on their website these hard hats are rated Type 1 Class C-G-E under ANSI Z89.1 and CSA Z94.1-15.

Disclaimer:

The first thing to remember, like the vast quantity of attachments on the market for other safety-related issues, when adding the SEEME-NOW Hard Hat Safety LED tape lights, the Class of the hard hat is changed. Still remaining with its strength for impact protection at 100% of manufacturing date the class rating of “C” remains constant. However, the electrical component of class E and G are now removed. Do not wear if an electrical shock could be possible.

Due to our new disclaimer, FreeBird Safety Services also feels it is our obligation to advise all workers that under no circumstances should any workers be working in close proximity to any electrically charged devices that would fall under the limits of approach. Power sources, open panels or any other systems that create a high hazard risk to electrocution should be locked out prior to starting a task. Unless specifically trained to do so, unqualified workers should never approach high voltage devices, lines, transformers or other device systems.

As illustrated in Table 19.1 of the WorkSafe BC regulations all workers must abide by the required limits of approach to energized circuits. The best and most common rule is to stay back at least 3 Meters or 10 feet. The only time any worker should enter within this zone is when a Lockout has been initiated and completed, and then only with permission of the person in charge.

For more information on the Attached LED Tape Lights see the following

YouTube Video

Hard Hat Lights

What are the Best Lights for Hard Hats?

or you can email us today at

[email protected]